products

Monochrome pad printer

Mixer Series

Screen Printer Series

Printing consumables

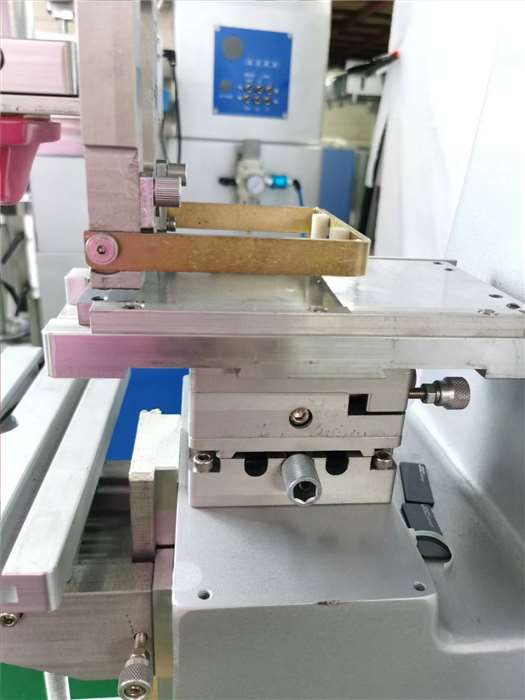

Monochromatic oil cup printing machine MINI/ p1

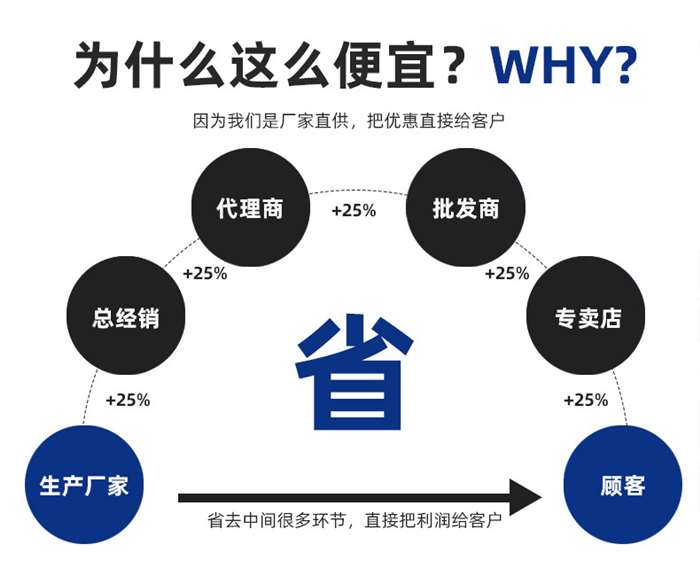

Dongguan Rihe Screen Printing Equipment Co., Ltd. was established in 2002. It is a professional research and development, design, production and sales of various printing equipment.

We focus on the manufacture of high-end pad printers, screen printers, and peripheral equipment for silk pad printing. With excellent cost performance and perfect pre-sale and after-sales service...

WE'RE HERE TO HELP

Easy ways to get the answers you need.

Contact Now

Easy ways to get the answers you need.

Application scope:

The oil cup pad printing machine is a high-end model of pad printing machines. During the printing process, the ink is completely sealed in the cup. After the viscosity of the ink is adjusted, it can always maintain good printing quality and stability. However, the high machine price and subsequent accessory costs make it difficult for many factory directors to accept. The newly developed small oil cup pad printing machine can use thin steel sheets and thick steel plates, and there are more options for controlling the cost of consumables (choose the oil cup pad printing machine to experience a higher quality pad printing process).

Technical parameters:

1. Single chip IC compilation action program, multiple printing mode selection

2. Automatic four digit counter to count printing quantity

3. Fully cast aluminum body, with a metal baked paint surface

4. Workbench, rubber head position can be X Y. Z-axis can be adjusted arbitrarily

5. The pressure of the ink suction and printing adhesive head is independently adjustable

6. Adjustable oil scraping stroke

7. Equipped with automatic forward and backward sliding ink leveling function to prevent local ink solidification

8. All cylinders have independent adjustment knobs for speed

9. Using imported pneumatic components

10. The adjustment positions are marked with scales

11. The whole machine runs fast, smoothly, and has low noise

12. Environmentally friendly oil cup design, easy and fast installation

13. Action mode selection: fully automatic | semi-automatic | self programming

14. Starting method: Panel | Foot switch

15. Scraper working mode: Pneumatic mechanical valve drives the cylinder up and down

16. Front and rear travel: 125MM

17. Up and down stroke: 50MM

18. Maximum printing area of the pattern: ¥ 50MM

19. Oil cup diameter: ¥ 90MM

20. Oil cup knife material: ceramic

21. Steel plate size: 100 * 200MM

22. Steel plate thickness: 0.3MM thin steel plate, 10mm thick steel plate

23. Printing station: 1 position

24. Fixture fixation method: T-shaped groove tabletop, compression code compression

25. Selection of Fixture Materials: Atomic Grey | Aluminum | Electrical | Plastic | Steel

26. Rubber head fixation method: wooden screw locking